- admin@qiangyiwood.cn

- Southwest Corner, Intersection of Nanwu Road & Nanhuan Road, Jiangnan Industrial Park, Gangnan District, Guigang City, Guangxi, China

Products

E0/E1 grade Melamine MDF board

Product Details Description

| Size | 1220x2440mm/1220x2745mm |

| Thickness | 9mm/12mm/15mm/18mm,etc |

| Core material | Wood fiber |

| Surface | Melamine paper/matt/glossy |

| Moisture | 8-12% |

| Certificates | CARB-P2/EPA/CE/FSC/ISO,etc. |

| Thickness tolerence | +0.2mm /-0.5mm |

| Environmental grade | E0/E1/E2 |

| Application | Home decoration/Cabinets/wardores/furniture,etc. |

Medium-density fiberboard (MDF) is mainly made from wood fibers. It has high-density and medium-density fiber board, with densities ranging from 680 to 830 kg/m³. Many people now use MDF instead of plywood for furniture making because it is cheaper and easier to work with.

Here’s some feature for MDF/HDF board:

- Medium fiberboard with more smoother face than plywood abd particle board.

- It can coated with melamine face for different color option, some people use it for furniture will need coated with melamine paper.

- It’s waterproof and moisture resistance. when it’s in high density and make into green core, it with this feature.

- It’s easy to cutting but it’s not much better than plywood in nail-holding capacity.

Application

Main products: Marine plywood, Melamine plywood, Melamine blockboard, Melamine Chipboard, Melamine MDF board, Film face plywood, Edge banding, Furniture accessories

Livingroom kitchen furniture ENF glue laminate plywood

Application: Children's Rooms/Nurse Rooms furniture Complete Kitchen furniture Bedroom furniture Elderly Room furniture Good choice for below Scene: medical and elderly care institutions Extreme cold snowfields High-temperature space Drying Challenge

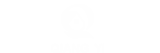

2026 all design melamine color glutinous rice plywood for school hospital office furniture

Functional summary of Qiangyi glutinous rice glue plywood: All climates – no need to worry about cold, heat, dryness, or humidity Full-featured – No need to worry about missing feature All scenarios – no need to worry about scenario applications Full life cycle

3/4 4x8ft AA wood core waterproof fireproof melamine face plywood for furniture

Health Protection & Environmental Convenience – Super ENF-grade Environmental Protection Health Protection, Peace of Mind – Odorless, Ready to Move In Protect your health and breathe with peace of mind – Anti-mold and antibacterial Durable Structure, Enduring Value – Stronger Nail Holding Power and Greater Resistance to Deformation Durable structure, lasting beauty – waterproof, moisture-proof, and expansion-resistant Durable structure, lasting beauty – 9.5 level termite resistance Durable structure, lasting beauty – anti-aging, crack-resistant Safety and Prevention: B1 Flame Retardant Super energy-saving and ultimate comfort – heat and sound insulation

Guangxi Eucalyptus core waterproof termiteproof melamine face laminate plywood for villa project

Superior materials: Selected top-quality raw materials, using Grade A logs, ensuring a tight fit, and using fully integrated core boards. Ultra-long cold pressing: 24 hours of slow cold pressing, with the Lingmei glutinous rice glue generating heat to ensure a tight bond between the board and the glue. Super drying: After 60 hours of slow drying, the moisture content inside the board is guaranteed to be uniform. Full curing: The finished boards undergo an extended curing period of 15 days, resulting in more stable and superior board performance.

Best Price Melamine Veneer/ Natural Color MDF Board 4*8 ft for Bed Room Wardrobe – Qiangyi PLYWOOD

The Features of MDF Board: The surface of MDF board is extremely smooth and flat. Easy to process and shape. Strong decorative potential. Cost-effective with high value. E0 Glue Eco-friendly. Density 680kg-800kg/m³.

Competitively Price E0 Grade MDF 18mm Board Natural Color for Wardrobe -Qiangyi PLYWOOD

MDF board has a dense texture and a relatively high wood content, especially suitable for making shaped cabinet doors. MDF board suitable for complex shapes: particularly commonly used for "shaped door panels" that require carving or milling of various lines and curves, such as European-style cabinet doors and wardrobe doors. If no special treatment is required on the surface, a natural-colored fiberboard can be chosen. Its natural color does not compromise the aesthetic appeal of the furniture. Its color is typically light yellow or light brown. This type of fiberboard can be used for the base and internal structures of furniture, such as wardrobes, bookshelves, and bed frames.Get more information about the plywood

What Should You Consider When Using White Melamine Particle Board in Contemporary Furniture?

White Melamine Particle Board Overview What is White Melamine Particle Board? White melamine particle board functions as one type of engineered wood product. Manufacturers make it by attaching pleasing melamine paper onto a particleboard core. This method mixes appearance and utility. The result is an even, steady white finish that works for simple, current furniture and inside spaces. Melamine particle board uses a particle (chipboard) base board along with melamine paper. Factories form the material via high-heat pressing. Customers like the final item for its tidy look, adaptability, and strong lasting power in cabinetry, shelving, and office furniture. Key Characteristics of White Melamine Particle Board Durability: White melamine particle board endures normal wear. The melamine-covered surface fights off scratches, water, and usual home stains. This property suits the board for spots with lots of movement. Low Maintenance: The sealed, level surface eliminates extra painting or coating. Cleaning calls for just a wet cloth. Lightweight & Sturdy: White melamine particle board is lighter than real wood, but it gives adequate support for common jobs. The board holds its form in shelving, wardrobes, or desktops. Benefits of White Melamine Particle Board in Modern Furniture Aesthetic Appeal A new panel of white melamine board lines walls and fits today’s tastes for room designs. Light softly reflects from the surface. This trait cuts down shadows and adds a more spacious feel in rooms by day. Glass or wood objects placed next to white melamine particle board catch eyes with quiet differences rather than sharp ones. The board has natural toughness, which man-made materials supply as standard. Room setups depend on these features more than most notice, since they hold against breakdown under the flat cover. Builders use melamine board to wrap up furniture and cabinets. Functional Durability White melamine particle board matches busy places like kitchens or offices. The board keeps its starting look through the years with basic care. White melamine particle board handles everyday harm. The surface holds together with routine upkeep. This factor fits the board for steady use. Cabinet doors, office desktops, and built-in shelves gain the most from white melamine particle board. Cost Efficiency and Accessibility White melamine particle board gives firmness next to solid wood or top laminates. Standard sizes cover 1220×2440mm and 1220×2745mm. White melamine particle board has approvals like CARB-P2, EPA, CE, FSC, and ISO. Low price keeps quality and stock steady. Thickness choices include 16mm and 18mm. Finishes offer matte or glossy types. These picks match small house tasks and major changes. Practical Considerations Before Choosing White Melamine Particle Board Intended Use and Load Requirements Users must review load needs before choosing white melamine particle board for a task. Shelves or counters carrying big weights need thicker panels (e.g., 18mm) to lock in support. Moisture Exposure Risks The melamine coat supplies basic water guard, but particle board might swell if edges meet ongoing wetness. Edge sealing stops growth from moisture. Wet rooms, such as bathrooms or laundry spots, call for QIANGYI’s multifunctional plywood with glutinous rice glue to gain stronger water resistance. The test report for the glutinous rice glue multi-functional board covers eight aspects: 0 benzene emission, Class II waterproofing, termite-proof, fire retardant Compatibility with Hardware and Fasteners Hardware, such as hinges or drawer slides, needs exact drilling to block splits. Special screws or inserts lock in grip and boost the structure’s life. Design Flexibility in Furniture Applications Popular Uses Kitchen Cabinets and Drawers: White melamine particle board builds orderly, solid cabinet faces that are easy to wipe in kitchens. Closet Systems and Wardrobes: The bright white coat boosts the view inside wardrobes and helps with neat keeping. Office Desks and Storage Units: White melamine particle board adds a work-ready look with handy daily traits. Wall Panels and Decorative Features: Setup runs quickly, and white melamine particle board matches feature walls or standing panels in work and living zones. Customization Options QIANGYI PLYWOOD offers custom picks for color, thickness, size, and edge banding. Support OEM service for specific requirements(color/veneer/thickness, etc.) Edge banding in white or other tones lifts design appeal. Surface styles cover matte for a calm vibe or gloss for light, to fit different tastes. See Our “New Design” Collection Live. To stay ahead of market trends, QIANGYI PLYWOOD is launching exclusive new textures and patterns at the 15th Guangzhou Custom Home Furnishing Exhibition this March. Visit Booth 6E13 to explore our latest melamine finishes that perfectly mimic natural grain and stone textures, designed specifically for high-end contemporary furniture. Installation Tips for Optimal Results Handling and Cutting Techniques Blades with fine teeth lower chipping while cutting. Steady backing below the panel in cuts halts edge harm or snaps. Assembly Practices Pre-drill spots before adding screws to cut split risks. Brackets or dowels firm up links where needed, mainly in heavy-duty setups. Maintenance Guidelines for Long-Term Performance Cleaning and Daily Care Regular wipes using a wet cloth manage cleaning. Strong cleaners hurt the melamine coat, so users avoid them. Preventing Damage Protect pads below heavy or sharp things, block dings or spots. These actions keep the style and use going for a long. Environmental Impact and Sustainability QIANGYI PLYWOOD stresses clean ways of making. Recycled wood bits usually build the core, which trims trash. Particle boards, including white melamine types, reach ENF formaldehyde emission marks. All of our products meet the national ENF environmental protection standard. For tighter green codes and safety in spots like kids’ rooms or hospitals, QIANGYI’s multifunctional glutinous rice glue plywood hits super ENF grade with emissions of ≤0.025mg/m³ and no scent after install. Glutinous rice glue functional laminate plywood rates ultra-ENF grade, environmentally friendly. At 35°C and 70% relative humidity, the formaldehyde release stays the same despite heat changes. FAQ Q: Is white melamine particle board waterproof? A: The surface gives basic water resistance from the melamine layer, but the core remains open to damp. In wet spots, QIANGYI’s multifunctional plywood provides Class II waterproofing performance. Q: Can white melamine particle board be used for kitchen cabinets? A: Yes. White melamine particle board offers a neat look and simple upkeep, which fits cabinet doors and shelves nicely. In areas near water, QIANGYI’s glutinous rice glue plywood adds extra toughness. Q: How eco-friendly is QIANGYI’s white melamine particle board? A: QIANGYI PLYWOOD supplies boards certified under CARB-P2, EPA, ISO, CE, and FSC standards with ENF-grade emissions, which guarantee safe indoor air quality. Q: Can I request custom sizes or finishes of plywood products from QIANGYI? A: Yes. QIANGYI supports OEM service for particular needs (color/veneer/thickness, etc.). QIANGYI delivers complete custom options, including thickness (16mm–18mm), edge banding colors, gloss levels, and even core material choices. Q: What makes QIANGYI’s multifunctional plywood better than standard particle board? A: QIANGYI’s multifunctional plywood employs Lingmei glutinous rice glue that lacks formaldehyde, resists mold, slows fire (B1 level), repels water (Class II), defends against termites (9.5 level), withstands cracks (Level 5), and stays environmentally secure for delicate spaces like children’s rooms or healthcare facilities. For furniture makers who seek dependable quality, eco-friendliness, and design options in large-scale or custom work, white melamine particle board by QIANGYI PLYWOOD supplies a reliable choice supported by years of advances in panel production.

How Does Melamine Laminated Marine Plywood Perform in Tough Environmental Conditions?

What Makes Melamine Laminated Marine Plywood So Durable in Extreme Conditions? The Role of Melamine in Enhancing Surface Strength Melamine laminated marine plywood features a strong outer layer of melamine resin. This layer boosts surface performance. The melamine resin forms a hard, scratch-proof covering. The board keeps its look in busy settings. This quality suits furniture and cabinetry. Both looks and wear resistance count there. Melamine offers more than strength. Melamine fights moisture, stains, and heat well. The surface handles moisture, stains, and heat in damp spots like bathrooms or kitchens. The even finish gives a clean, nice style. No extra paint or seal is needed. QIANGYI PLYWOOD provides melamine plywood in different feels—matte, glossy, embossed—and in custom colors to fit any design plan. Why Marine-Grade Core Materials Matter The core of this product is marine-grade. This sets it apart from regular plywood. The product uses fine hardwood layers with few empty spots. This builds solid strength and cuts weak areas that take in water or fail under load. The layers bond with waterproof glues for a good hold against splitting. Melamine-laminated marine plywood holds up in high humidity. QIANGYI PLYWOOD’s multifunctional plywood picks eucalyptus for the core. Eucalyptus stands out for its tight grain, strength, and germ-fighting traits. All plywood comes from wide eucalyptus logs. This yields steady, top-grade boards. These traits make it the top pick for load-bearing jobs in damp spots. How the Manufacturing Process Increases Longevity QIANGYI PLYWOOD’s making steps focus on care and strength. High-pressure lamination bonds layers tightly. Exact pressing removes air pockets and boosts build quality. The board takes mechanical force without bending or cracking. A key step is curing. The Glutinous Rice Glue Functional Laminate Plywood dries for 60 hours and sets for 15 days. This long cure builds chemical protection and surface toughness. The board gains better protection against steady wear and weather effects. Built for Demanding Applications Ideal Uses in Wet or Humid Environments Melamine-laminated marine plywood works well in high-damp spots. The build and coating handle moisture. Builders use it for boat interiors, kitchen cabinets, bathroom vanities, and yard furniture. Our Glutinous Rice Glue Functional Laminate Plywood holds a Class II strong water-proof rating. The board keeps form and power after long, damp contact. The board soaks in water for 24 hours. Water uptake growth stays at just 2.4%. This makes QIANGYI’s multifunctional plywood solid for shore builds and business spots like eateries and health centers. Cleanliness and damp fight matter there. Resistance to Warping, Swelling, and Mold Growth QIANGYI’s glutinous rice glue multifunctional plywood fights typical plywood problems like bending and mold. The firm core stops growing or shrinks from heat shifts. The board stays straight through yearly damp changes. Factory seals cover edges. Sealed edges cut the water entry chance. This stretches product life in rough weather. QIANGYI Glutinous Rice Glue Functional Laminate Plywood scores 0 on mold rating. An antibacterial rate over 99% backs this. The product stays clean and safe over time. Comparing Marine Plywood with Other Types of Plywood Differences Between Standard Plywood and Marine Plywood Marine plywood differs from standard plywood in build and action. Marine plywood resists water better and has fewer core holes. Marine plywood proves stronger in damp contact. Standard plywood breaks down fast in water. Swelling or layer split follows. Marine-grade boards like QIANGYI’s multifunctional glutinous rice glue board offer steady work under ongoing dampness. Benefits of Choosing Melamine Laminated Over Plain Marine Plywood Marine plywood stands firm on its own. The melamine layer adds ease of use. The melamine layer brings strength without more finish work. The board installs right away—great for quick builds or fix-ups. The melamine surface cleans fast with a wipe. The surface fights daily scratches. Cleaning and upkeep stay simple. The surface looks fresher longer. QIANGYI’s products mix style with work. How to Choose the Right Melamine Laminated Marine Plywood for Your Project Key Factors to Consider Before Buying Pick melamine laminated marine plywood with care for the core grade and glue kind. QIANGYI Glutinous Rice Glue Functional Laminate Plywood uses top first-grade core sheets. Check if glue hits ENF or HENF formaldehyde rules. Match board thickness to project load needs—QIANGYI PLYWOOD gives choices from 5mm to 25mm—and select from many custom melamine feels and colors to match room styles. Tips for Installation and Maintenance Boost life at setup with water-proof seal on cut edges. The design fights water, but skips long stretches in pools of water. Clean surfaces with non-scratch tools. This keeps the melamine layer sound and the setup nice for years. Why Trust QIANGYI PLYWOOD for Quality Products? QIANGYI PLYWOOD ranks as a known name in Guangdong, with over two decades in fine board making. The company grows smart making methods and has built four bases in Guigang, Guangxi, covering over 100,000 square meters. What truly sets us apart is our full-chain making process—from glue mix to board build—which holds quality tight. We ensure that each sheet faces hard checks before shipment, and we test every batch before factory exit. Experience Our Quality Live at CCHF 2026 To demonstrate our commitment to quality and innovation, we invite you to inspect our products firsthand. QIANGYI TRADE will be showcasing our latest “New design” collections and marine-grade boards at the upcoming industry showcase: Event: The 15th Guangzhou Custom Home Furnishing Exhibition Date: March 27th – 30th, 2026 Location: Poly World Trade Center Expo, Guangzhou Booth: 6E13 (Poly Hall 6, 3rd Floor — The same exhibition hall as the CIFF fair) We welcome you to visit our 160.5m² booth to discuss how our eco-friendly, zero-formaldehyde solutions can benefit your projects. What Other Products Does QIANGYI PLYWOOD Offer? Beyond our signature marine plywood, we provide a versatile range of building materials: Melamine Laminated Particle Board: This board cuts costs and is used by builders for custom furniture, offering varying print options and even surface quality. Film Faced Plywood: A tough, reusable phenolic coat makes this fit for concrete forms, chosen by construction pros for its strength. Commercial Plywood: This fits many jobs, providing steady action at a low cost for cabinetry and inside finishes. MDF with Melamine Finish: With a smooth face and good size hold, this board suits shelf units, closets, and decor panels. Looking for Reliable Building Materials That Last? Pick QIANGYI PLYWOOD’s melamine-laminated marine plywood when strength counts. Whether for wet environments or busy commercial spots, our products provide firm work that holds. FAQ Q: What makes melamine laminated marine plywood suitable for bathrooms or kitchens? A: The damp-proof core pairs with a scratch-proof melamine face. Swelling, bending, or marks stay away—perfect for wet zones like bathrooms or kitchens. Q: Is QIANGYI’s multifunctional plywood environmentally friendly? A: Yes. Glutinous rice glue functional laminate plywood hits ultra-ENF grade for green use. Zero formaldehyde leaves even in heat or damp. Q: Can I get customized sizes or finishes of plywood boards from QIANGYI PLYWOOD? A: Absolutely. QIANGYI gives custom picks. Thickness runs from 5mm to 25mm. Surface types include matte or glossy. Colors or feels match needs. Q: How long does melamine-laminated marine plywood last? A: Proper setup and care bring a 15-year warranty. QIANGYI’s boards handle long work in tough spots. Q: What glue is used in QIANGYI’s multifunctional plywood? A: Our Glutinous Rice Glue Functional Laminate Plywood uses zero-formaldehyde Lingmei Glutinous Rice Glue. Plant parts like glutinous rice flour and magnesium oxide form the base.

Exploring the Benefits and Applications of Melamine Plywood in Furniture Design

What is Melamine Plywood? Melamine plywood consists of engineered wood panels formed by attaching melamine resin-soaked paper to plywood, MDF, or particle board bases. This process produces a sturdy, attractive layer that copies the look of wood or various patterns, providing visual charm and practical benefits. Melamine board possesses strong qualities that natural wood lacks, which leads to its common use in interior design and the finishing of different furniture pieces and cabinets. QIANGYI PLYWOOD provides melamine plywood with surface choices like matte, textured, glossy, embossed, and wood grain patterns to fit various style requirements. The surface stays flat and spotless, which makes care and wiping straightforward. Key Differences Between Melamine Plywood and Traditional Wood Panels Melamine plywood differs from traditional wood panels through improved strength and easy-care features. Melamine plywood board comes from a plywood core combined with melamine paper, shaped via high heat pressing. The main benefits include environmental safety, scratch resistance, heat tolerance, rust prevention, water resistance, plus simple handling. Natural wood fails to match this even surface quality in large quantities, so melamine plywood suits custom furniture making. Functional Advantages of Melamine Plywood in Everyday Use Durability and Structural Integrity QIANGYI PLYWOOD’s melamine plywood resists bending and splitting under substantial loads. Melamine plywood maintains form even during routine handling. Melamine plywood performs effectively for load-bearing components in furniture such as shelves, cabinets, and wardrobes. Thickness tolerance measures +0.2mm / -0.5mm, ensuring dimensional consistency in mass production. Resistance to Environmental Stressors Melamine plywood avoids color changes from sun exposure and handles dampness and warmth without lifting or expanding. Low Maintenance Requirements Mild soaps suffice for cleaning melamine surfaces. The solid layer blocks stains from entering, which cuts down on care work for residents. Chemical resistance remains standard, and the material endures wear from typical substances like acids, bases, oils, and alcohol. Enhancing Everyday Furniture Functionality with Melamine Plywood Applications in Kitchen Cabinetry and Storage Units QIANGYI’s melamine plywood performs well in kitchen settings because of solid defense against vapor, warmth, and dampness. Use in Bedroom and Living Room Furniture Wardrobes and media stands built with QIANGYI’s melamine plywood keep their form and shade through the years. The even finish aids current style elements such as push-open mechanisms or cabinets without handles. Color variations in one batch stay small, which boosts overall visual flow. Integration into Office Desks and Shelving Systems QIANGYI melamine plywood’s scratch-proof layer guards against harm from office tools. Options in basic shades like white oak or walnut grain patterns blend with workspaces while offering strong wear protection. Sustainability Considerations of Melamine Plywood Products Efficient Use of Raw Materials in Production QIANGYI employs eucalyptus core or fir core in melamine plywood, usually from quick-growth plantations. We receive tight oversight on raw materials and at each step. This approach lowers reliance on slow-maturing hardwood types. Long Product Lifespan Reducing Waste Generation The prolonged service of QIANGYI melamine and multifunctional plywood cuts down on replacements, which conserves supplies and limits waste in landfills. Our boards include a 15-year warranty, which shows our plywood products’ dependability and eco-friendliness. Compatibility with Eco-Friendly Certifications and Standards QIANGYI products comply with tough eco rules like CARB-P2, EPA, CE, FSC, and ISO certifications. All of our products meet the national ENF environmental protection standard, which aids green construction efforts. Design Flexibility Enabled by Melamine Surfaces Types of Finishes Offered: Glossy, Matte, Textured QIANGYI melamine plywood supplies surface types for shiny luxury or modern flat styles to suit preferences. The raised patterns bring tactile interest to upright surfaces. Color Options Mimicking Woodgrains or Solid Hues QIANGYI delivers tailored patterns that echo high-end items like walnut or marble for less expense. Melamine Color: Solid color or, as the client’s request, supporting personalized furniture designs. Customization Possibilities for Mass Production CNC Machining Compatibility Melamine plywood works with CNC cutting for exact connections, vital for current custom furniture. Edge Banding Techniques QIANGYI PLYWOOD also supplies matching PVC edge banding for a smooth look. Edge banding is a process in woodworking where a strip of material is applied to the edges of a piece of furniture to give it a finished look and protect the edges from damage. Factors Affecting Performance Over Time Importance of Proper Installation Techniques Correct edge covering during setup avoids edge puffing or separation. The wrong attachment causes separation under pressure. Maintenance Practices That Extend Lifespan Cleaning Guidelines Steer clear of rough cleaners that could dim melamine patterns with time. Handling Precautions Heavy items require lifting to avoid surface marks from sliding. Comparing Cost-Efficiency with Alternative Materials Initial Investment vs Long-Term Value Melamine plywood costs more at first than basic particle board, but its strength and reduced care yield savings in the long run. Furthermore, QIANGYI also provides Glutinous Rice Glue Functional Laminate Plywood, which serves as a second-generation multi-layer plywood, providing better endurance. Performance Metrics Compared to Veneer or Laminate Panels Durability Under Load QIANGYI multifunctional plywood shows firm nail-holding power (2040 MPa) and defense against shape changes. Resistance to Daily Wear The scratch-proof layer shields from routine damage more effectively than regular veneer layers. Aesthetic Retention Over Years Stable melamine layers hold their look without turning yellow or losing color in sun contact. FAQ Q: Can QIANGYI melamine plywood be customized for specific furniture designs? A: Yes. Support OEM/ODM service for specific requirements (color/veneer/thickness, etc.) is available for all melamine plywood products. Q: Is melamine plywood safe for children’s rooms? A: QIANGYI Glutinous Rice Glue Functional Laminate Plywood is ideal for children’s rooms due to its Super ENF grade environmental protection and antibacterial properties. Q: How does QIANGYI ensure consistent product quality? A: From raw material procurement to finished product delivery, there are a total of 28 quality inspection processes. Q: How soon can I move in after installing QIANGYI multifunctional plywood? A: Under normal renovation conditions, it can be installed and moved in immediately.

Understanding the Production and Types of Melamine Plywood

Overview of Melamine Plywood Definition Melamine plywood is an engineered wood panel formed by heat-pressing melamine resin-impregnated decorative paper onto a plywood core. This combination creates a board that merges decorative aesthetics with structural strength. Melamine board has good properties that natural wood cannot have. People often use it in interior architecture. They also apply it in the decoration of various furniture and cabinets. Core Components Melamine plywood typically comprises two main components: Core Material: MDF (Medium Density Fiberboard) Particle Board Multilayer-CorePlywood Blockboard Surface Layer: A melamine resin-impregnated decorative paper that can simulate textures such as wood-grain, stone, and abstract patterns. Role of Melamine Resin Melamine resin enhances surface durability and resistance to moisture, scratches, and abrasion. As a thermosetting resin, it cures permanently under high heat and pressure. This process creates a stable and smooth outer layer. Manufacturing Process of Melamine Plywood Core Material Selection Core selection directly affects the mechanical strength, weight, and screw-holding capacity of melamine plywood. For instance, denser cores like eucalyptus offer better durability. Companies prefer them in QIANGYI’s Glutinous Rice Glue Functional Laminate Plywood. Preparation of Melamine Paper Decorative paper is first soaked in melamine resin. Then workers dry it to form a hardened sheet available in matte, gloss, or textured finishes. QIANGYI supports various finishes including PET, embossed, and magic textures for customized orders. Hot Pressing Process The impregnated paper is layered over the plywood core and hot-pressed to ensure adhesion. This step creates a tight bond between the core and the decorative surface. Cooling and Finishing After hot pressing, panels are cooled to stabilize their structure. Workers then trim and cut them into standard sizes like 1220×2440mm or customized dimensions. Quality Control Every board must withstand the test of all weather conditions. This fulfills our quality commitment of “Environmentally friendly and powerful, choose QIANGYI PLYWOOD for quality”. Tests include moisture resistance, surface flatness, and adhesion strength checks. Types of Melamine Plywood Classification by Core Material MDF Core: Smooth surface ideal for painting. Particle Board Core: Lightweight and cost-effective. Veneer-Core: Best for structural applications with good screw-holding strength. Classification by Surface Finish Options include: Gloss Matte Textured QIANGYI PLYWOOD offers extensive choices for surface customization to match decor requirements. Functional Variants Waterproof Melamine Plywood: Suitable for humid environments. Fire-Retardant Melamine Plywood: Glutinous rice glue functional laminate plywood achieves a B1 flame retardant rating. Antibacterial Panels: QIANGYI Glutinous Rice Glue Functional Laminate Plywood has a mold resistance rating of 0, which means it won’t grow mold and has an antibacterial rate of >99%. Standard Thickness Options Thin Panels: 5 mm/9 mm Standard Panels: 12 mm / 15 mm / 18 mm — widely used in furniture manufacturing. Edge Treatment Options PVC Edge Banding Highly flexible with excellent color matching; suitable for most furniture applications. ABS Edge Banding More eco-friendly than PVC; offers better impact resistance and is recyclable. Wood Veneer Edge Banding Provides a natural wood look while preserving melamine surface functionality. Solid Wood Edging Used in high-end applications where edge strength and aesthetics are critical. Advantages of Melamine Plywood High Durability: Scratch-resistant and long-lasting. Moisture Resistance: Our Glutinous Rice Glue Functional Laminate Plywood has a Class II strong waterproof function,making it suitable for humid environments. Design Versatility: Available in multiple finishes and colors. Low Maintenance: Easy to clean with a simple wipe. Lightweight & Stable: Easy handling during construction. Common Applications Furniture Manufacturing Melamine plywood is widely used in cabinetry, wardrobes, desks, and shelving units due to its aesthetic flexibility and durability. Interior Decoration Ideal for wall cladding and partitions in both residential and commercial interiors. Retail and Commercial Use Frequently used in display units, fixtures, exhibition booths due to its easy customization. Work Surfaces Office desks and light-duty counter-tops benefit from its scratch-resistant surface. Comparison with Other Engineered Boards Compared to Traditional Plywood Melamine plywood offers better aesthetics but is less tolerant to repeated heavy screw fastening unless reinforced with high-density cores like eucalyptus. Compared to Laminated Particle Board Melamine plywood has a harder surface and superior wear resistance, especially when made with QIANGYI’s Glutinous Rice Glue technology. Selection Considerations Thickness Selection Choose thicker panels (18mm or more) for structural components like shelves or platforms; thinner sheets (5–9mm) suit backing or drawer bases. Color and Texture Matching QIANGYI PLYWOOD provides customized melamine color options including woodgrain, marble grain, matte, gloss, PET, etc., allowing harmony with any interior scheme. Core Quality Evaluation QIANGYI Glutinous Rice Glue Functional Laminate Plywood uses only the highest quality, first-grade materials for its core panels. Maintenance Guidelines Cleaning Recommendations Use soft cloths with mild soap or cleaners; avoid abrasive tools that may damage the surface. Preventive Care A hot pot should never sit on a hard surface – place it instead on a protective mat or board to keep from getting injured by sharp edges or scalds. Limitations and Environmental Considerations Even though melamine plywood lasts a long time, keep it away from strong warmth like kitchen stoves or household heaters for too long. Glutinous rice glue functional laminate plywood is ultra-ENF grade environmentally friendly, and you can move in immediately after installation. However, like all engineered wood products, melamine boards are not biodegradable and should be recycled responsibly. FAQ Q: What makes QIANGYI’s multifunctional melamine plywood different from standard boards? A: QIANGYI Glutinous Rice Glue Functional Laminate Plywood uses Lingmei glutinous rice glue, which forms a dense crystalline structure after curing, making it highly resistant to deformation, flame retardant, antibacterial, and waterproof. Q: Can melamine plywood be used in kitchens or bathrooms? A: Yes, especially QIANGYI’s multifunctional plywood which is Class II waterproof and suitable for humid environments like kitchens and bathrooms. Q: Is there any smell from QIANGYI’s melamine plywood after installation? A: QIANGYI Glutinous Rice Glue Functional Laminate Plywood has no odor, so you can move in immediately after installation. Q: Can I customize the color or surface texture of the plywood? A: Yes, QIANGYI PLYWOOD offers full customized service including colors like woodgrain or marble grain as well as textures like matte or gloss finish. Q: Is QIANGYI’s melamine plywood safe for children’s rooms? A: For children’s rooms, we recommend our QIANGYI Glutinous Rice Glue Functional Laminate Plywood… its environmental protection level reaches Super ENF grade, and it has no odor. For more information or to request customized samples of melamine plywood or multifunctional plywood, please contact QIANGYI PLYWOOD directly — trusted by over ten thousand households nationwide.

Melamine Sheets: Applications, Benefits, and Why Choose Them

Introduction: The Rise of Melamine Sheets In recent years, melamine sheets have gained growing use in residential and commercial interior design projects. Melamine sheets deliver varied looks, low cost, and strength. These features position melamine sheets as a preferred surface option for designers, contractors, and homeowners. Designers, contractors, and homeowners apply melamine sheets in kitchen cabinets, wardrobes, or office furniture. Melamine sheets provide a premium appearance without the steep expense of natural wood. QIANGYI PLYWOOD stands as a main player in this market, and functions as a skilled manufacturer of plywood. The company holds over 20 years of experience. QIANGYI PLYWOOD runs four ecological board production bases. These bases produce 20,000 pieces each day. QIANGYI PLYWOOD supplies a broad selection of melamine products. This selection delivers custom solutions. The solutions address the changing demands of current interiors. What Are Melamine Sheets? Melamine sheets consist of engineered wood panels. Workers bond resin-infused decorative paper to a substrate like particleboard or MDF. Melamine Plywood board uses a plywood base board and melamine paper. High-temperature hot pressing forms the board. This process creates a firm outer layer. The firm outer layer looks good. The layer also shows high durability. Melamine sheets come in many kinds of textures, patterns, and finishes. These range from natural wood grains and marble effects to solid colors in matte or glossy choices. Surface options include melamine paper, matte, high-gloss, and more. Such versatility allows melamine sheets to fit almost every design style. How Melamine Sheets Differ from Other Laminates A main benefit of melamine sheets over traditional high-pressure laminates (HPL) involves cost. Melamine plywood forms through high-temperature hot pressing. Its chief benefits cover environmental protection, wear resistance, high temperature resistance, corrosion resistance, waterproof, simple and convenient, and a variety of patterns and colors. Melamine results from a low-pressure process. The low-pressure process shortens manufacturing time. The process also lowers costs. Melamine sheets perform well in terms of durability. Melamine sheets resist scratches, stains, and impacts. These sheets work in high-traffic areas. The surfaces require little care. Cleaning remains easy. The surfaces need only a damp cloth for upkeep. This upkeep differs from the heavy care required for natural wood. Key Benefits of Choosing Melamine Sheets Cost-Effective Surface Solution Melamine sheets deliver an upscale look for a minor fraction of the price of solid wood or veneer. Projects with tight budgets want upscale style. Melamine sheets provide the proper balance for those aims. QIANGYI PLYWOOD provides affordable and quality Melamine Sheets. These sheets feature custom options. The options satisfy specific needs. Options include size, thickness, core material, and finish. Wide Range of Design Options Melamine sheets supply a broad choice of colors and patterns. Choices include wood grain, marble texture, solid hues, and PET finishes. This choice offers strong design freedom. The surface treatment options include matte, textured, glossy, embossed, or magic. These options enable matching any interior style from minimalist to industrial. Exceptional Durability and Resistance Melamine sheets withstand moisture, heat, scratches, and impacts. Such properties allow melamine sheets to perform well in damp zones like kitchens and bathrooms. The surface stays smooth and clean. The surface proves easy to maintain and clean. This ease brings lasting satisfaction despite regular use. Versatile Applications Across Industries Melamine sheets serve from home furniture to office workstations and retail fixtures. Melamine sheets are applied in different sectors. Uses cover home decoration, cabinets, wardrobes, and furniture. These uses render melamine sheets among the most flexible materials available. Applications of Melamine Sheets Residential Interior Applications Kitchen Cabinets and Shelving: Melamine sheets suit kitchen settings because of their resistance to moisture and stains. The chemical resistance proves general. It withstands wear from common solvents such as acid, alkali, grease, and alcohol. Wardrobes and Bedroom Furniture: Smooth finishes add grace to bedrooms. The finishes keep installation light and useful. Commercial and Office Use Office Desks and Workstations: Melamine sheets endure daily use. The sheets allow custom branding with different finish options. Retail Fixtures and Display Units: Resistance to fingerprints and scuffs suits melamine sheets for spots with much customer contact. Comparing Melamine Sheets with Other Surface Materials Melamine vs. Traditional Laminate Boards Common laminate boards use high-pressure lamination methods. Such methods often increase production time and costs. Melamine sheets arise from low-pressure lamination. This process proves more affordable. The process also delivers adequate strength for usual indoor uses. Melamine vs. Natural Wood Finishes Natural wood may require sealing or polishing over time. Melamine’s simple-care trait makes it much more practical for long-term use. Melamine also brings large savings in initial costs and regular upkeep fees. Technological Innovations Enhancing Melamine Sheet Performance QIANGYI PLYWOOD leads in innovation. The company applies current printing techniques. These techniques reproduce natural grain patterns. The techniques reach clear detail. QIANGYI PLYWOOD melamine sheets feature anti-bacterial coatings. The sheets also feature anti-fingerprint technologies. Such features support hygiene in kitchens or bathrooms. The focus on sustainability appears clear. Recycled materials in the core boards reduce environmental effects. Quality stays the same. This approach matches green building standards such as LEED. Why Melamine Sheets Are a Smart Choice Today Melamine sheets balance beauty, performance, and affordability well. Fit with current minimalist and modern designs makes melamine sheets quite relevant. Neutral tones and smooth finishes come through QIANGYI’s custom solutions. Melamine sheets match changing style tastes smoothly. Conclusion: Melamine Sheets Are the Ideal Choice From looks to performance, cost savings to eco-friendliness, melamine sheets stand out in every way. Those seeking quality Melamine Sheets should view QIANGYI PLYWOOD. QIANGYI PLYWOOD supplies a wide array of creative and fine options. These options suit diverse needs. Full custom choices exist there. Options range from thickness to surface texture. Such traits let users achieve any design vision. FAQ Q: What are melamine sheets commonly used for? A: Melamine sheets are typically used in furniture such as cabinets, wardrobes, office desks, retail fixtures, wall paneling, and shelving. Their durability and aesthetic flexibility make them a popular choice. Q: Are melamine sheets waterproof and suitable for high-moisture areas like kitchens and bathrooms? A: Yes, melamine sheets are moisture-resistant, making them a great choice for high-moisture areas such as kitchens, bathrooms, and laundry rooms. Unlike natural wood, melamine resists water absorption, which helps prevent swelling and warping, ensuring long-lasting performance in these environments. Q: How long do melamine sheets last? A: With proper installation and basic upkeep, melamine sheets endure for many years. The scratch-resistant and impact-resistant surface supports this. Q: Can I get customized melamine sheets from QIANGYI PLYWOOD? A: Absolutely. QIANGYI PLYWOOD supports OEM service for specific needs (color/veneer/thickness, etc.). This service meets project demands exactly. Q: Is melamine better than laminate for furniture, cabinetry, and indoor applications? A: For most indoor applications such as furniture, cabinetry, and light business settings, melamine is a budget-friendly alternative to laminate. It offers adequate durability for home use and provides a cost-effective solution for projects that require a balance between quality and affordability.

Glutinous rice Plywood vs Traditional Wood: What You Should Know

The construction and furniture sectors change quickly. A rising need for strong, safe, and green materials drives this shift. Glutinous rice plywood also name as multifunctional plywood gains ground. The second-generation glutinous rice plywood replaces traditional wood products in homes and business areas. 1. What is Multifunctional Glutinous Rice Plywood? Multifunctional glutinous rice plywood goes by the name QIANGYI All-Weather Glutinous Rice Board from QIANGYI PLYWOOD. Experts view the product as the second generation of multi-layer plywood. People call the product the “Nine-Sided Warrior”. The product excels in nine main areas. These areas include environmental protection, zero benzene emission, waterproofing, moisture resistance, mildew-proof, antibacterial, termite-proof, flame-retardant, and anti-deformation. Core Composition and Science Core Material:Top-grade Grade I eucalyptus core boards. The Adhesive:Proprietary glutinous rice glue. Formula: A special mix of glutinous rice starch, magnesium chloride, magnesium oxide, and water. After the glue gelatinizes, it becomes ceramic-like. The network shows physical strength and chemical steadiness. Physical crystalline bonding forms the basis of the structure. Unstable chemical reactions do not factor in. Long-term durability results. The durability matches the enduring mortar in the Great Wall of China. 2. Industry Evolution: The Failure of Traditional Urea-Formaldehyde (UF) Resin Traditional plywood relies on Urea-Formaldehyde (UF) resin. The chemical structure lacks stability. Heat and humidity trigger a “reverse reaction” in UF resin. Chemical bonds break down in the reaction. Formaldehyde is released into the air. The process causes several issues: Continuous Aging:The glue weakens gradually as decomposition occurs. Surface Cracking: Internal bond breakdown leads to cracks or peeling on the decorative surface. Indoor Air Pollution: Formaldehyde releases steadily, sometimes for years. QIANGYI PLYWOOD Industry started in 2004. The company brought in glutinous rice glue technology. Our technology removes these risks from the start. 3. Core Technology Comparison: Stability and Craftsmanship Structural Integrity UF Resin Plywood:Heat and moisture speed up breakdown. The board turns brittle with time. Glutinous Rice Plywood: The crystalline structure stays firm and avoids breakdown. The coefficient of thermal expansion remains very low. Anti-cracking and anti-aging performance stands out. Manufacturing Precision QIANGYI multifunctional plywood boards follow stricter standards than regular plywood in production: Selection of Materials:Grade I core boards and large-diameter eucalyptus serve as the only choices. Traditional UF boards blend materials of mixed quality. Thick glue covers flaws. Layer-by-Layer Coating: Glutinous rice glue shows high permeability. Layer-by-layer coating becomes necessary. A “full continuous core” layout follows. Transparency prevents the hiding of inferior materials in layers. The 20-Day Cycle: One board requires about 20 days to produce. This includes 60 hours of controlled drying and a 15-day seasoning period to lock the moisture content in the “golden range” of 8%–12%. 4. Performance Peak: The Full-functions Advantages Environmental Safety and Indoor Air Quality Glutinous rice glue boards reach Ultra-ENF levels. The levels mark the top industry standard. Zero Benzene:The production process avoids formaldehyde, benzene, or phenols. Temperature Stability: UF boards double formaldehyde release with heat. QIANGYI PLYWOOD boards hold steady at 35°C and 70% humidity. Instant Move-in:The boards carry no smell. Families can move in right after installation. B1-Grade Fire Safety Safety matters greatly in public and home areas. Magnesium oxide in the adhesive works as a basic flame retardant. High Melting Point: Magnesium oxide reaches a melting point of 2852°C. Carbonization Strategy:Fire exposure prompts the dense crystal structure to block oxygen. Hours of exposure lead to carbonization only. Flames do not spread. Waterproofing and Moisture Resistance Water poses the biggest threat to wood. Multifunctional plywood satisfies Class II waterproofing standards. Swelling Control:National standards allow up to 8% expansion in 24-hour water absorption. QIANGYI PLYWOOD boards limit expansion to about 2.4%. Total Protection:Glue soaks into wood fibers. Water molecules cannot enter. Resistance to Termites and Mold Magnesium-based glue creates an alkaline setting. The setting offers ongoing biological defense. Termite-Proof:The rating hits the 9.5 level. Glue’s alkaline quality kills termites that eat the fibers. Mildew-Proof:The product earns Grade 0. No growth occurs. Toxic fungi stay in check even in wet coastal or tropical areas. Antibacterial:Bacterial inhibition rate exceeds 99%. 5. Cost and Long-Term Value Multifunctional plywood costs more upfront than basic brands. Long-term value proves much better: Lower Maintenance:Defense against pests, mold, and cracks removes repair needs. Health Benefits: No VOCs or toxic releases safeguard resident health. Children and older people benefit most. Quality Guarantee: A 15-year warranty backs the boards. Twenty-eight quality checks support the warranty. 6. Advanced Application Scenarios Residential Use Kitchen & Bath:Class II waterproofing makes the product perfect for cabinet units. Children’s Room: Ultra-ENF grade safety and zero odor create a poison-free space. Elderly Care:Magnesium oxide serves as a solid sound blocker and heat shield. Better sleep follows. Commercial & Specialty Projects Public Buildings:B1 fire safety and strong durability satisfy tough safety rules for schools and hospitals. Full-Height Wardrobes:Physical firmness holds doors up to 2.8 meters high. Warping does not happen. Fast-Track Renovations: No chemical odor allows quick partial remodels. Occupancy starts right away. 7. Quality Control and Logistics QIANGYI PLYWOOD runs four smart manufacturing sites in Guangxi. Space covers over 100,000 m². The company partners with the Guangxi Product Quality Inspection Institute for standard labs. How to verify genuine QIANGYI PLYWOOD boards: .Invisible Mark: UV light uncovers the “QIANGYI series” hidden mark on the surface. Exclusive Label: An official factory label appears on every board. Section Stamp: Detailed product and batch info prints on the board side. 8. Conclusion: The Board of the Future Multifunctional glutinous rice plywood goes beyond a simple material improvement. The product signals a basic change in wood methods. Natural, crystalline bonding replaces shaky chemical adhesives. Healthier, safer, and tougher boards result compared to standard options. Modern homes, business projects, and public sites benefit. The “Nine-Sided Warrior” suits future needs for green and healthy settings. FAQ Q: What is multifunction plywood made of? A: QIANGYI multifunctional plywood comes from glutinous rice starch, magnesium chloride, magnesium oxide, and water. These components deliver strong fire resistance and solid moisture protection. Q: Is multifunction plywood safe for indoor air quality? A: Yes. Glutinous rice glue boards release zero benzene. These boards meet HENF formaldehyde standards. Such features support improved indoor air quality. Q: Can multifunctional plywood be used outdoors? A: Yes. Apply protective coatings to seal QIANGYI multifunctional plywood correctly. Use the sealed plywood in semi-outdoor settings, such as facades or garden furniture. Water-resistant qualities enable this application. Q: How does multifunction plywood compare to regular plywood in terms of durability? A: QIANGYI multifunctional plywood surpasses regular plywood for durability. The material resists termites, mildew, and fire. QIANGYI multifunctional plywood maintains structural stability during shifts in temperature or humidity. Q: Why choose QIANGYI PLYWOOD products? A: QIANGYI provides tested eco-friendly panels along with certifications that include CARB P2, EPA, CE, FSC, and ISO. QIANGYI PLYWOOD boasts over 20 years of manufacturing experience. Nationwide distribution networks operate with good efficiency.

If you interested in our product, please leave you information here, we will send you more details

Please fill out the form below and we will get back to you as soon as possible.